https://www.engadget.com/2018/12/24/bugatti-tests-3d-printed-titanium-brake-caliper/

Volkswagen Group

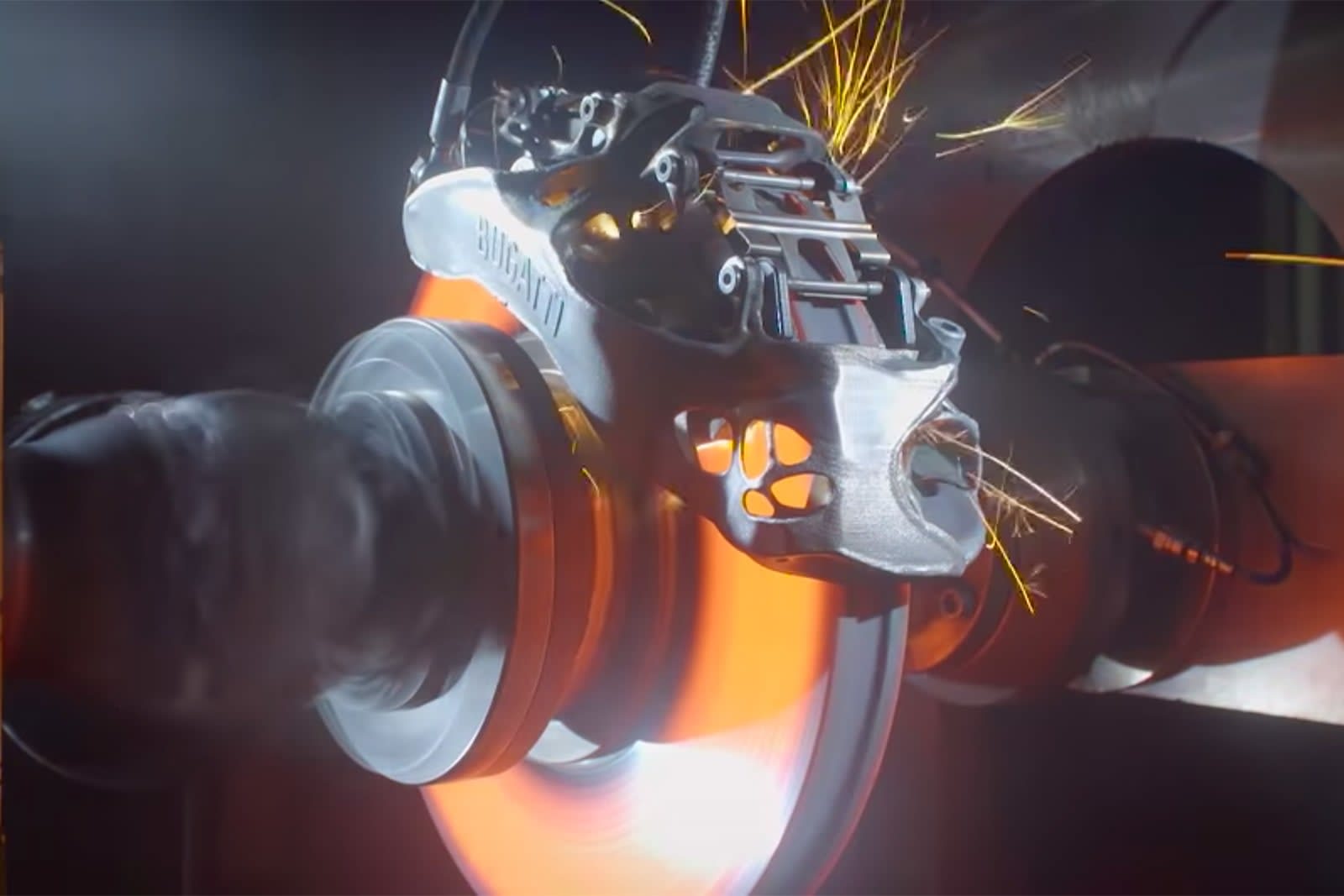

Back at the start of 2018, Bugatti revealed that it was working on the first 3D-printed brake caliper. Now that the year is winding to a close, it’s finally ready to show the caliper in action. Bugatti has posted a video (below) of a test that simulated braking at speeds as high as 249MPH. As you might imagine, it was quite the show — the disc alone reached temperatures up to 1,877F, and there were plenty of flames and sparks as the caliper and disc reached their limit.

This isn’t just about pyrotechnics. The caliper should eventually go into hypercars like the Chiron and Divo, where the lighter-than-usual weight and greater strength could be vital to both agility and stopping in a hurry.

Just don’t expect to see 3D-printed calipers in ordinary Volkswagen Group cars any time soon. It takes about 45 hours to melt and shape titanium using four lasers. That’s fine for a multi-million-dollar luxury vehicle that will be sold in very small numbers, but it won’t work for mass production. Bugatti’s next quest is to speed up production to the point where 3D-printed tech is available in volume. If it can do that, you might see calipers like this in decidedly more affordable rides.

via Engadget http://www.engadget.com

December 24, 2018 at 07:36AM